Repairing Bone Fractures: Nano-Coated Magnesium Alloys a Good Option

Alloys of magnesium are being considered as a good option for orthopedic applications as magnesium is biocompatible, biodegradable and has other important mechanical properties.  Magnesium is the fourth abundant metal in the body and is known to accelerate the healing of bones. Taking leads from these researchers from the Indian Institute of Technology Madras (IIT Madras) have developed nano-coated magnesium alloys that can repair bone defects in rabbits. The research team is planning to study medical applications of nano-coated magnesium alloys in other animals and repairing human bones.

Magnesium is the fourth abundant metal in the body and is known to accelerate the healing of bones. Taking leads from these researchers from the Indian Institute of Technology Madras (IIT Madras) have developed nano-coated magnesium alloys that can repair bone defects in rabbits. The research team is planning to study medical applications of nano-coated magnesium alloys in other animals and repairing human bones.

However, the use of magnesium alloys in bone repair is restricted due to a few issues. These issues have given a major push to the field of synthetic bone biomaterials where materials such as hydroxyapatite, calcium phosphate, and titanium, among others, are being used for filling the bone gaps.

Prof. MukeshDoble, Department of Biotechnology, IIT Madras, said, “Bones such as the fore-arm, back-arm, leg and thigh which are almost one-foot-long are called ‘long bones’ in the body. Small fractures or defects can be treated with plates and rods. Fractures longer than 5 cm are called long bone segmental defects, which take a long time to heal and need some sort of support. Titanium mesh cage is placed in the gap which helps to heal and stabilize the bone. But it does not degrade and so remains in the body permanently. It also leads to stress shielding since it has mechanical strength much larger than the bone.”

Also Read : Public Health Systems are Not Machines to Make Money: Address WHO’s Structural Flaws

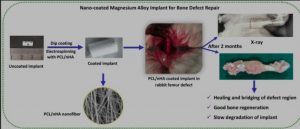

Further, Prof. MukeshDoble added, “Magnesium is now being looked at as an option as it can degrade slowly and reabsorbed. Its mechanical properties are also closer to that of the bone. The main problem with magnesium is that it degrades fast. To slow it down and match to the growth of the new bone, we have coated (electrospinning) it with a slowly-degrading polymer called ‘polycaprolactone’ mixed with ‘hydroxyapatite.’ The latter is the same as the bone material and hence, does not cause any toxicity and integrates with the bone.”

For this study, the researchers deployed the AZ31 alloy of magnesium and used it for developing magnesium mesh cage implants. Further, they coated these implants with polycaprolactone and nano-hydroxyapatite by dipping and electrospinning. This nano-coated magnesium mesh was then used to heal the bone defect in the femur of rabbits.

The researchers found that the rabbit femur implanted with the coated magnesium alloy showed bone formation and also bridged the defect region. The team emphasizes that this was possible due to the biocompatible nature of polycaprolactone and nano-hydroxyapatite which ensured good recovery without any adverse reactions such as ‘fibrosis.’

The research team includes Prof. Mukesh Dobleand Dr.GovindarajPerumal, IIT Madras, Dr. Boopalan Ramasamy, Christian Medical College, Vellore, Dr. A Maya Nandkumar, Sree ChitraTirunal Institute for Medical Sciences and Technology, Thiruvananthapuram, Dr. D. Sivaraman, Sathyabama Institute of Science and Technology, Chennai and Dr. R Selvaraj from Bioscience Research Foundation, Chennai. The research findings have been published in the journal Nanomedicine. (India Science Wire)